The Electrastart Weld Checker Spot Weld Monitor Front Panel

Download Brochure

Reseller Enquiries Welcome

‘The Weld Checker’

EWM-1 SPOT WELD MONITOR

No need to ever create faulty or weak, “out of spec”, spot welds again!

The ESL Weld Checker is a measurement and alarm unit designed for operation with all types of spot welders.

The Weld Checker measures the energy content of the weld, as it is forming, and compares it to upper and lower levels of acceptability.

The Weld Checker is specifically designed to release the skilled machine setters and supervisors from constant monitoring of production spot welding.

There are several parameters that affect spot weld quality:

-

Power Level

-

Squeeze Pressure

-

Weld Time

-

Tip Shape

-

Tip Condition

-

Material Condition

As these parameters vary with time and wear, the effect is indicated on the digital display.

Therefore, the Weld Checker also performs the role of diagnostic tool during machine setting and troubleshooting.

At the end of each weld, the Weld Checker compares the measured energy of the weld against preset

values determined by the machine setter during setup.

The result of the comparison is signaled by either a green light for OK, or one of two red alarm lights – high

or low.

The alarm condition is also indicated by a brief high-pitched audible tone.

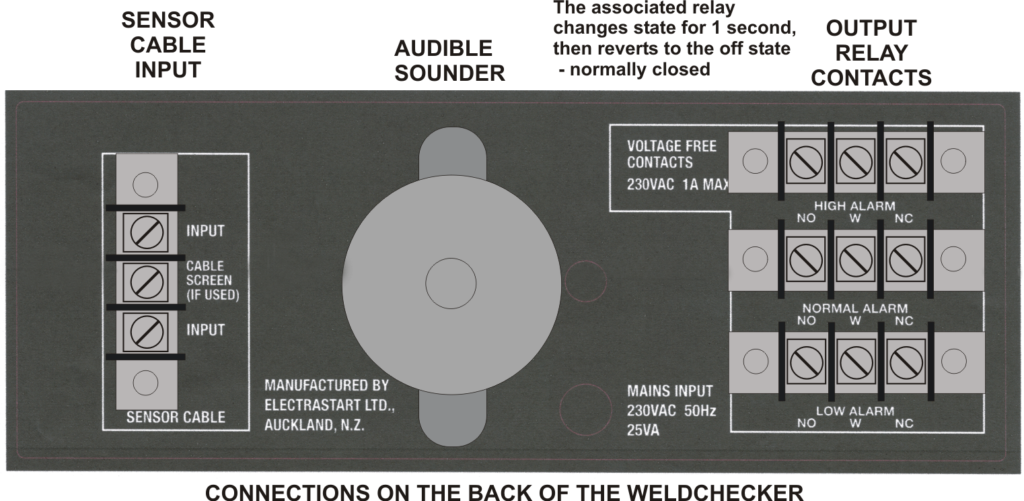

Each of the three conditions also has associated relay contacts which change state briefly,

for use in external monitoring or control applications.

FEATURES

-

- Simple operation – can be put into immediate productive use.

- Spring-loaded clips ease connection to welding

arms/electrode holders. (Easily removed for

permanent connection of sensor wires to welder). - No mechanical alteration to the welder is required to

fit or remove the weld Checker.

Unique measurement method detects effects of electrode wear on weld quality –

indicates when to tip dress electrodes before they affect quality.

The detailed manual describes different methods for determining set points with the goal of having alarms

indicating the time for maintenance before creating faulty welds.

Applying the Electrastart Weld Checker Spot Weld Monitor

Enquiries:

All information supplied is used for the sole purpose of answering enquiries.

No information is passed on to any third party.